|

Mississippi

County Community College

(870) 763-6222

|

THE

SOLUTIONS

GROUP |

Customized Training

for Today's Workplace

|

Training offerings in the science

of precision machining blend classroom instruction with hands-on practical

application to provide participants with both a solid knowledge base and

development of skill competencies. Training offerings range from basic

milling, turning, and sharpening operations to geometric dimensioning &

tolerancing to jig fixture & design to Computer Numeric Control (CNC)

programming to tool & die making.

Hands-on training equipment at the

MCCC Harry L. Crisp Center used in the delivery of precision machining

training include:

-

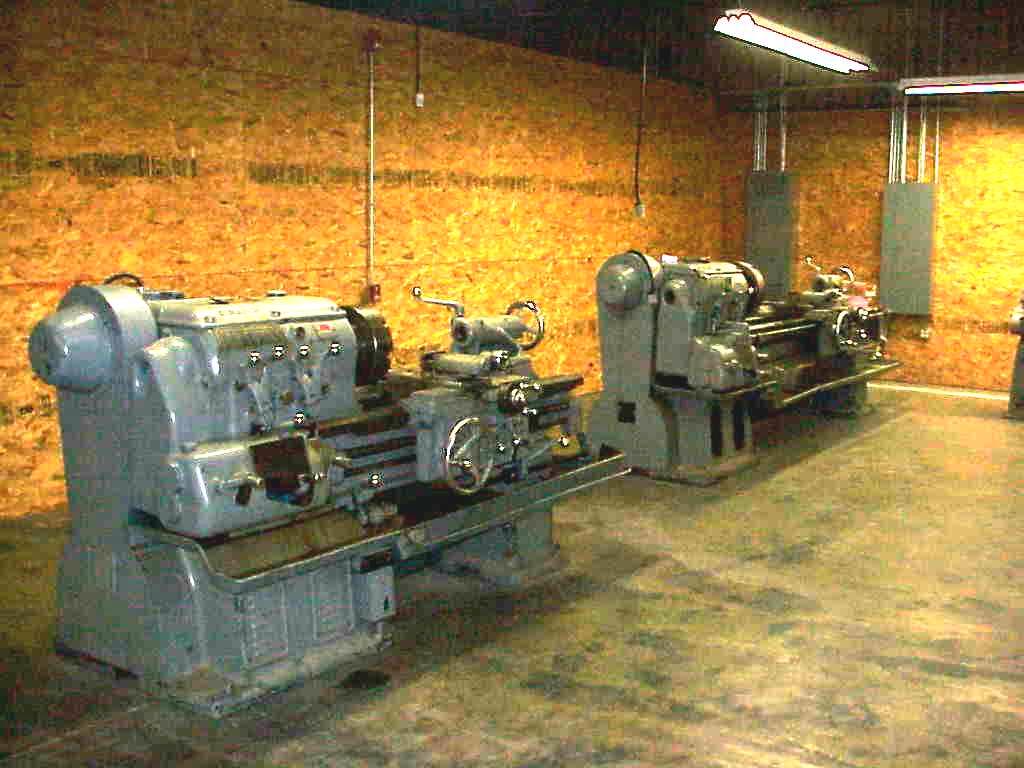

Machining Lab

– fully equipped with industrial grade machines and associated tooling

and workstations for practical application of manually controlled machining

operations

-

Lathes

-

Vertical mills

-

Surface grinders

-

Radial drill

-

Sandblaster

|

Lathes

|

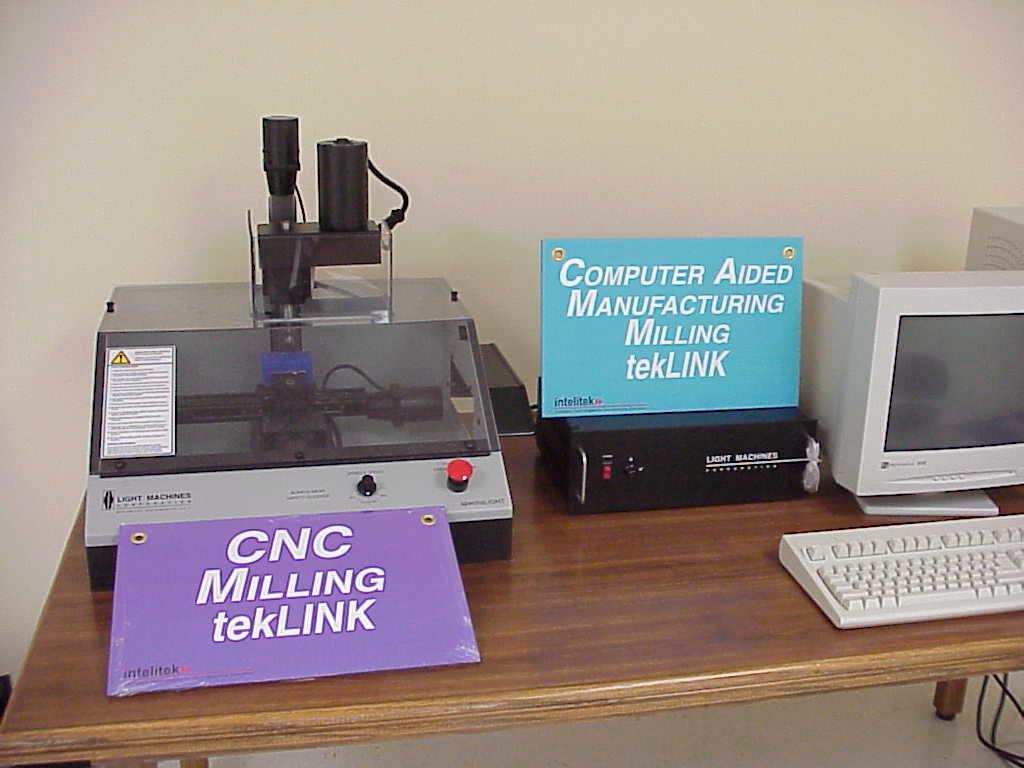

CNC Mills

|

|

|

-

CNC Milling Training

System – Participants gain hands-on experience in proper machine

set-up, cutting tools selection, tool path simulation, and machining center

operation in designing solutions for industrial CNC milling applications:

-

Tool path generation

-

Contouring

-

Engraving

-

Pocketing

-

Machining operations for ruled and swept

surfaces

-

Code generation

The milling center is supported by

computer aided manufacturing (CAM) software to provide the connection between

computer aided drafting (CAD) designs and CNC manufacturing by incorporating

the machining codes within the CAD file.

-

CNC Turning Training

System – Participants gain hands-on experience in proper machine

set-up, cutting tools selection, tool path simulation, and machining center

operation in designing solutions for industrial CNC turning applications:

-

Roughing

-

Facing

-

Grooving

-

Threading

-

Cut-off procedures

-

Code generation

The turning center is supported by

computer aided manufacturing (CAM) software to provide the connection between

computer aided drafting (CAD) designs and CNC manufacturing by incorporating

the machining codes within the CAD file. [Available

for training Fall 2000]

-

Maintenance Welding

Training Station – designed to deliver a hands-on training leading

to welding experience for maintenance technicians charged with the task

of repairing and fabricating parts for modern production and packaging

machines. The training station is furnished with:

-

Oxyacetylene setup

-

Stick (Shielded Metal Arc) welding

machine

-

MIG (Gas Metal Arc) welding machine

-

Resistance welding machine

-

Plasma cutter

The training system will allow

the training of safe welding practices using multiple techniques and will

build competencies in welding a variety of joints from different positions,

spot welding, and plasma cutting and brazing.

[Available for

training Fall 2000]

Return to Home Page